The importance of filtration in the food industry

Correct design of food handling, processing equipment and food manufacturing facilities is more important than ever before. As we move forward with the implementation of food safety programmes, it becomes very important to give more scrutiny to hygienic design of facilities and equipment for the entire food supply chain.

For starters: air is everywhere. In almost all food processes, even closed ones, food gets into contact with the air surrounding it.Untreated compressed air contains many potentially harmful or dangerous contaminants which must be removed or reduced to acceptable levels in order to protect the consumer and provide a safe and cost effective production lines.

Not changing filters regularly will result in over saturated filters, preventing effective removal of bacteria. This results in the consumer product becoming contaminated and unfit for consumption.

By not choosing the correct air handling, you leave yourself open to the following risks:

- Over saturated filters resulting in damage to important equipment.

- Contaminated product, resulting in products unfit for consumption

- Contaminated product going out to the public leaving the company open to possible fines and legal action

- Negative publicity if a contaminated product reaches the market

- Depending on the severity of the contamination, the whole plant could be shut down pending government investigation

All these result in a massive increase in production costs that far outweigh the yearly maintenance cost needed to make sure all the air handling equipment meets the strict guidelines for food safety.

Why choose Ultrafilter products?

To make sure we can guarantee the best solution to our customers, our products are now approved by the EHEDG (European Hygienic Engineering & Design Group). This way you can be sure our products meet the strict guidelines for the food industry.

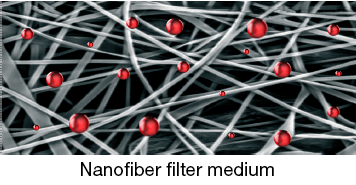

Our filters use the nano fiber technology

- Multi layer, binder-free nano-fiber media, made of borosilicate nano-fibers with a void volume of over 98 %.

- The three-dimensional construction extends the service life and filtration performance by effectively separating larger solid particles in the pre-filterlayer.

- Oleo-phobic – actively rejects oil and water, thus reducing differential pressure.

- Nano-fibers are 10 times finer than micro-fibers

Contact us

Need some more information?

Feel free to contact us with any questions about our filters and filter elements.